Sustainable development

General information about sustainable development management in the company

Rosseti Tyumen JSC pays considerable attention to a comprehensive and balanced sustainable development while driving business towards it.

The Company by updating the technological expertise, expanding production capacities, and commissioning new production facilities influences the socio-economic development of the operating area through the job creation and paying taxes to the local budget.

The Company, when rendering power transmission and grid connection services in three constituent entities of the Russian Federation: Tyumen Region, the Khanty-Mansi Autonomous Okrug - Yugra and the Yamalo-Nenets Autonomous Okrug, supports the population and the development of all economy sectors in Western Siberia. Rosseti Tyumen strives to consistently implement the principles of sustainable development in its operational and management processes. The approach to sustainable development is based on constant interaction with stakeholders and a systematic assessment by the Company of its impact on the economy, environment and society.

The company’s share in the power transmission market is 67.5%.

Rosseti Tyumen JSC supports all the sustainable development goals outlined at the UN summit in 2015 and strives to make a significant contribution to the achievement of the goals most relevant to the power industry.

Material Topics Management

Department of Economics and Tariff Setting

The Energy Strategy approved by Decree of the Government of the Russian Federation No. 1523-r dd. June 9, 2020 On approval of the Energy Strategy of the Russian Federation until 2035

Regulations on the Credit Policy of Rosseti Tyumen JSC (approved by Board of Directors of Rosseti Tyumen JSC No. 30/20 dd. November 16, 2020)

Order of Rosseti PJSC No. 438 dd. September 25, 2020 On the Credit Policy of the Subsidiaries and Affiliates of Rosseti PJSC

Investment Policy of Rosseti OJSC approved by Board of Directors of Rosseti OJSC No. 174 dd. December 19, 2012

The Policy for Innovative Development, Energy Saving and Energy Efficiency Improvement of Rosseti PJSC (approved by Board of Directors of Rosseti OJSC, Minutes No. 150 dd. April 23, 2014; Board of Directors of Tyumenenergo JSC, Minutes No. 08/14 dd. June 24, 2014)

Development Strategy of Rosseti PJSC and its Subsidiaries and Affiliates (the Rosseti Group) up to 2030 (approved by Board of Directors of Rosseti PJSC, Minutes No. 388 dd. December 26, 2019)

Regulations of Rosseti PJSC

On the Uniform Technical Policy in the Power Grid

- resolution of the Board of Directors of Rosseti PJSC (minutes No. 450 dd. April 2, 2021);

- resolution of the Board of Directors of Rosseti Tyumen JSC (minutes No. 17/21 dd. July 9, 2021)

Decree of the Government of the Russian Federation No. 511-r dd. April 3, 2013 (as amended on November 29, 2017) On Approval of the Strategy for the Development of the Electric Grid Complex of the Russian Federation

Decree of the Government of the Russian Federation No. 3924-r dd. December 28, 2021 On approval of the Strategy of Digital Transformation of the Fuel and Energy Complex

Investment DepartmentMajor Construction Department

Procurement Policy of Rosseti OJSC (approved by Board of Directors of Tyumenenergo OJSC No. 11/14 dd. July 31, 2014)

Regulations of Activities of the Central Procurement Commission of Rosseti Tyumen JSC (approved by Order No. 323 dd. August 31, 2021)

Order of Rosseti Tyumen JSC No. 48 dd. February 10, 2021 On approval of the Anti-Corruption Activities Plan 2021 in Rosseti Tyumen JSC”

Order of Rosseti Tyumen JSC No. 351 dd. August 28, 2020 On the Enactment of a New Version of the Anti-Corruption Policy of Rosseti PJSC and the subsidiaries and affiliates of Rosseti PJSC.

Order of Rosseti PJSC No. 10 dd. January 15, 2020 On Corruption Prevention Measures in the Rosseti Group

Code of Corporate Ethics and Official Conduct of Employees of Tyumenenergo JSC (approved by Board of Directors of Tyumenenergo JSC, Minutes No. 16/17 dd. May 12, 2017, approved by the Order of Tyumenenergo JSC No. 311 dd. May 30, 2017 On the Adoption of the Code of Corporate Ethics and Official Conduct of Employees of Tyumenenergo JSC

Project Office

Department of Technological Development and Innovation

Innovative Development Program of Rosseti Tyumen JSC for 2020-2024 with a perspective up to 2030 (Board of Directors of Rosseti Tyumen JSC dd. July 6, 2021 (minutes No. 17/21 dd. July 9, 2021)

Innovative Development Program for 2020–2024 with a perspective up to 2030 (approved by Board of Directors of Rosseti PJSC (Minutes No. 447 dd. February 8, 2021)

Order of Rosseti PJSC No. 203 dd. October 14, 2019 On Approval of the Standard Methodology for Updating Innovative Development Programs of the subsidiaries and affiliates of Rosseti PJSC

Order of Rosseti PJSC dd. December 24, 2018 No. 568 approved the Technological Register for the Main Areas of Innovative Development of Rosseti PJSC

The “Digital Transformation 2030” Concept ( the Concept") approved by the resolution of the Board of Directors of Rosseti PJSC dd. December 21, 2018 (Minutes No. 336 dd. December 21, 2018)

Digital Transformation of Rosseti Tyumen JSC 2020-2030 Program (Board of Directors of Rosseti Tyumen JSC (Minutes No. 04/20 dd. January 31, 2020) (developed under “Digital Transformation 2030” of Rosseti PJSC Concept).

Development strategies of Rosseti PJSC and its subsidiaries (the Rosseti Group) up to 2030, approved by the resolution of the Board of Directors of Rosseti PJSC dd. December 26, 2019, minutes No. 388)

Program for the Development of Smart Metering in the Retail Electricity Market in the Rosseti Tyumen JSC’s grids for 2020–2030 (Board of Directors of Rosseti Tyumen JSC, minutes No. 04/20 dd. January 31, 2020)

Approval of the Program of Implementation of Smart Metering Systems in Rosseti PJSC Board of Directors of Rosseti PJSC, Minutes No. 428 dd. August 31, 2020)

Decree No. 177r dd. April 2, 2019 On approval of the Development Methodology for the Development of Smart Metering in the Subsidiaries and Affiliates of Rosseti PJSC

Order of Rosseti PJSC No. 190 dd. September 25, 2019 On approval of Scenarios for the Programs of Smart Metering Development

Order of Rosseti Tyumen JSC No. 412 dd. October 12, 2020 On the Enactment of a New Version of the Environmental Policy for the Electric Grid Complex (approved by Board of Directors of Rosseti PJSC (Minutes No. 422 dd. July 20, 2020))

Decree of Rosseti Tyumen JSC No. 260r dd. 08.12.2021 On Approval of the Action Plan for the Implementation of the Environmental Policy of the Electric Grid Complex for 2021–2022

Decree of the Government of the Russian Federation No. 340 dd. May 15, 2010 On Setting the Requirements for Programs in Energy Efficiency and Energy Conservation for Companies Engaged in Engaged Regulated Activities

Resolution of the Regional Energy Commission of the Tyumen region, KhMAO, YNAO No. 31 dd. 12.12.2019

The Policy for Innovative Development, Energy Saving and Energy Efficiency Improvement of Rosseti PJSC (approved by Board of Directors of Rosseti OJSC, Minutes No. 150 dd. April 23, 2014; Board of Directors of Tyumenenergo JSC, Minutes No. 08/14 dd. June 24, 2014)

The organization standard Regulations on the Occupational Safety and Health Management System in the Rosseti Group was approved under the Order of Rosseti PJSC No. 334r dd. July 27, 2018 On the Organizational Standard Approval

The Zero Injuries Action Plan “Vision Zero” in Rosseti Tyumen JSC

Order of Rosseti PJSC No. 143 dd. August 30, 2018 On approval of Rosseti PJSC Health and Safety Documents

Regulations on the Occupational Safety and Health Management System in the Rosseti Group, Occupational Safety and Health Policy of the Rosseti Group was approved under the Order of Tyumenenergo JSC No. 442 dd. September 11, 2018 On Acceptance of Occupational Safety and Health Area Documents for Execution

Finance Department

Development Strategy of Rosseti PJSC and its subsidiaries and affiliates (the Rosseti Group of Companies) up to 2030 (resolution of the Board of Directors of Rosseti PJSC (Minutes No. 388 dd. December 26, 2019)

Insurance Program of Rosseti Tyumen JSC for 2021 (approved by the Board of Directors of Rosseti Tyumen JSC No. 33/20 dd. December 21, 2020)

Regulations on insurance coverage in Rosseti Tyumen JSC as amended (approved by Board of Directors of Rosseti Tyumen JSC No. 18/20 dd. July 3, 2020) (approved by order of Rosseti Tyumen JSC No. 383 dd. September 28, 2020 On the Enactment of a New Version of the Regulation on Insurance in Rosseti Tyumen JSC)

Program of Non-State Pension for Employees of Tyumenenergo JSC for 2019 (approved by the Board of Directors No. 22/19 dd. September 30, 2019)

The collective agreement of Rosseti Tyumen JSC, on behalf of the employees signed by the Tyumen Interregional Organization of the Public Institution “All-Russian Electric Trade Union” Regulations on the Unified System of Remuneration for Workers, Managers, Specialists and Employees of Rosseti Tyumen JSC

Department of Economic Security and Anti-Corruption

Order of Rosseti Tyumen JSC No. 419 dd. October 27, 2021 On Approval and Enactment of the Regulations on the Commission of Rosseti Tyumen JSC for Compliance with Corporate Ethics and Settlement of Conflicts of Interest, Regulations on the Settlement of Conflicts of Interest in Rosseti Tyumen JSC

Order of Rosseti PJSC No. 477r dd. September 08, 2017 On approval of the Procedure for Organizing management-to-Employees Personal Receptions and Meetings in the SDCs of Rosseti PJSC, in branches and in production departments of branches of the SDCs of Rosseti PJSC

Order of Rosseti Tyumen JSC No. 12r dd. January 19, 2021 “On the implementation of the Procedure for Organizing management-to-Employees Personal Receptions and Meetings in the SDCs of Rosseti PJSC, in branches and in production departments of branches of the SDCs of Rosseti PJSC

Action Plan for Improving the Company’s Risk Management System (approved by Board of Directors of Rosseti Tyumen JSC, minutes No. 01/20 dd. January 15, 2020)

Investment Department

Major Construction Department

Investment program of Rosseti Tyumen JSC

Department of Industrial Safety and Production Control

Department of Information Security and Facilities’ Protection

Regulations on the Internal Technical Control System in Rosseti Tyumen JSC (approved by order of Rosseti Tyumen JSC No. 171 dd. May 14, 2021)

Regulations of Rosseti PJSC

On the Uniform Technical Policy in the Power Grid

- resolution of the Board of Directors of Rosseti PJSC (minutes No. 450 dd. April 2, 2021);

- resolution of the Board of Directors of Rosseti Tyumen JSC (minutes No. 17/21 dd. July 9, 2021)

Cooperation agreements with 24 educational institutions with field-specific chairs

Agreement on cooperation entered into between Rosseti Tyumen JSC, the Department of Education of Nizhnevartovsk, Nizhnevartovsk State University and Secondary School No. 5. Field-specific energy classes were opened in Nizhnevartovsk and Novy Urengoy

6 subsoil license agreements

Agreement with the Government of the Tyumen Region on ensuring reliable and high-quality power supply to the customer, on the planning of development of municipalities in terms of power grid facilities location and on the development of outdoor lighting networks, as well as on the development of the regional investment potential.

Regulations on the HR and Remuneration Committee of the Board of Directors of the Company (approved by Board of Directors of Tyumenenergo JSC No. 25/17 dd. September 21, 2017)

Regulations on the Committee for Grid Connection of the Board of Directors of Rosseti Tyumen JSC (approved by Board of Directors of Tyumenenergo JSC No. 14/20 dd. May 6, 2020)

Regulations on the Reliability Committee of the Board of Directors of Tyumenenergo JSC in a new edition (approved by Board of Directors of Tyumenenergo JSC No. 21/17 dd. July 18, 2017)

Regulations on the Strategy Committee of the Board of Directors of Tyumenenergo JSC (approved by Board of Directors of Tyumenenergo JSC No. 24/19 dd. November 1, 2019)

The Internal Audit Policy of Rosseti Tyumen JSC as amended (approved by Board of Directors of Tyumenenergo JSC No. 26/21 dd. December 29, 2021)

Regulations on the Board of Directors of Rosseti Tyumen JSC as amended (approved by Board of Directors of Rosseti Tyumen JSC No. 12/20 dd. April 28, 2020)

Order of Rosseti PJSC No. 610 dd. December 25, 2020 On Development of Friendly Environment for Small and Medium-Sized Enterprises

Department of HR and Organizational Design

Order of Rosseti Tyumen JSC No. 12r dd. January 19, 2021 “On the implementation of the Procedure for Organizing Management-to-Employees Personal Receptions and Meetings in the SDCs of Rosseti PJSC, in branches and in production departments of branches of the SDCs of Rosseti PJSC

Decree of Rosseti Tyumen JSC No. 78r dd. April 7, 2021 On approval of the Plan of Corporate, Sports, Festival and Anniversary Events of Rosseti Tyumen JSC in 2021

Council of Young Professionals of Rosseti Tyumen JSC Corporate website www.te.ru Intranet portal

Order of Rosseti Tyumen JSC No. 503 dd. November 30, 2021 On Approval and Enactment of a New Version of the Regulations on the Monthly Key Performance Indicators of the Personnel of Rosseti Tyumen JSC

Hr management

Hr policy implementation results

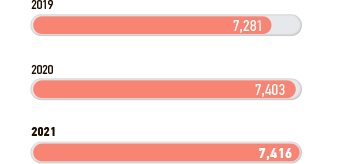

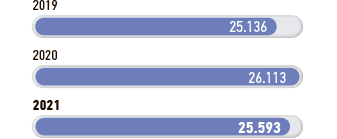

The headcount for 2021 was 7,416 people, which is 0.2% higher than in 2020. A slight increase in the headcount is due to the natural movement of personnel.

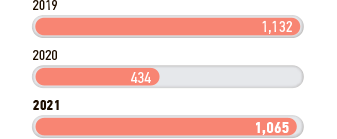

Headcount of Rosseti Tyumen JSC in 2019–2021, persons

Headcount of Rosseti Tyumen JSC: breakdown by branches in 2021

The staffing level of the Company’s production personnel is 96.6%.

Active turnover in 2021 was 6%.

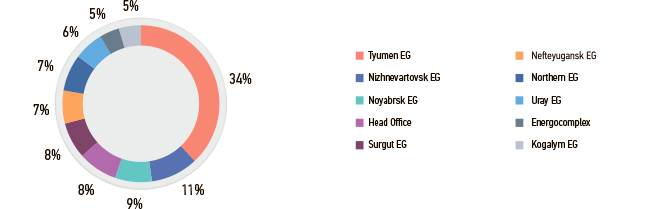

The average age of employees is 42 years. Rosseti Tyumen JSC is focused on rejuvenating the workforce through the implementation of measures and creating conditions for attracting young professionals. Thus, in 2021, the percentage of employees under the age of 35 admitted to the Company amounted to 49.2% of the total number of employed employees.

Almost half of the Company’s employees are aged 35 to 50 – 49%. Young workers under the age of 35 – 26%. There is a slight decrease in the percentage of employees in the category “over 50 years old” by 0.1 p.p. as compared to 2020.

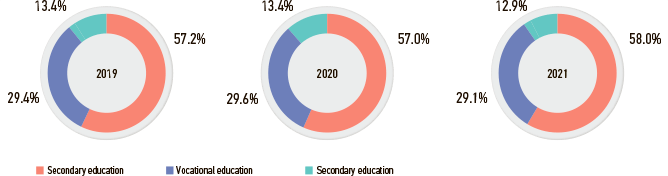

Staff breakdown by age in 2019-2021

Rosseti Tyumen JSC employs high skilled staff: 3 employees have a Ph.D. degree, 87.1% of the Company’s specialists have professional education, 23% of whom have higher education, a sign that the production staff is well trained.

Staff breakdown by education in 2019-2021

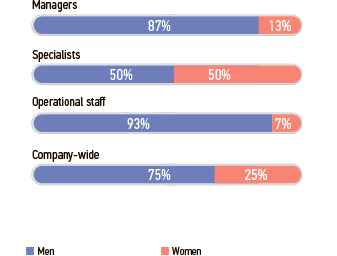

Percentage of women in each category of employees in 2021, %

number of employees

Societies

Breakdown by gender and type of contract, pers. (GRI 102-8 )

Number of employees: breakdown by type of contract and gender, pers. (GRI 102-8 )

Total number of employees: breakdown by type of contract and by subdivision (GRI 102-8 )

Employees hired in 2021: breakdown by age, gender and branches (GRI 401-1 )

Employees dismissed in 2021: breakdown by age, gender and branches (GRI 401-1 )

Staff training and development

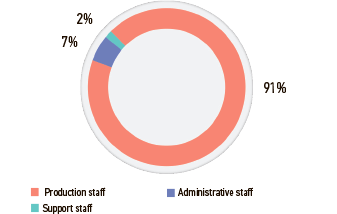

Staff training and career development is a key element of the Company’s HR policy: in 2021, 7,138 employees completed training programs, which is 96% of the Rosseti Tyumen JSC headcount. Most of the training programs were implemented with the use of distance technologies (71%).

The HR policy is aimed at developing the intellectual, professional and managerial potential of employees to implement the Company’s strategic priorities and the adopted concept of “Digital Transformation 2030”.

Training prioritizes engineering staff as well as the Company’s candidate pool. Production staff accounted for 91% (6,531) of those trained.

Breakdown of staff who completed training is given below.

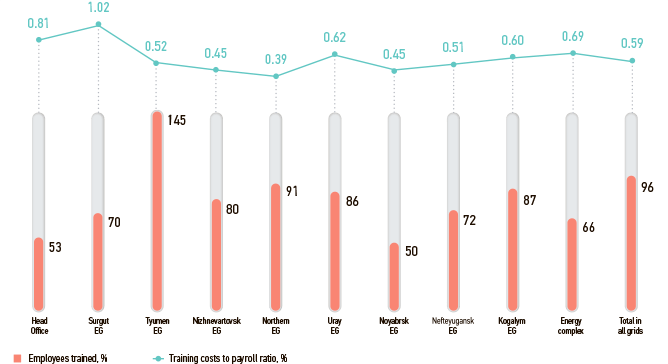

Percentage of staff trained and training costs to payroll ratio in 2021, %

Staff trained in 2021: breakdown by categories

In 2021, actual training costs totaled 0.6% of the payroll (0.5% in 2020).

On average, training time was 39 hours per employee in 2021.

Average training hours per employee: breakdown by gender and staff categories (GRI 404-1) ( GRI 404-1 )

The system of continuing education of the Company’s staff is based on the following principles:

- unconditional compliance with the frequency of mandatory types of employee training;

- prioritization of training programs aimed at developing innovative and digital competencies of employees;

- maintaining a balance between the development of advanced professional and corporate competencies.

The COVID-19 pandemic significantly adjusted the training process, including at the Company’s Corporate Training Center.

In 2021, Rosseti Tyumen JSC adopted 49 educational programs, the project of the Moodle-based corporate distance learning system was developed, the programs are being converted into the digital format. The launch of a distance learning system will ensure the continuity of production processes, improve the training effectiveness, and will also ensure the compliance with a single educational standard in a geographically distributed Company.

Besides, as part of internal corporate training, more than 1,000 employees of the Company participated in the Knowledge Day educational project aimed at improving professional competence, adapting new employees and creating a high-quality knowledge management system.

The system of continuing education created in the Company allows employees to perform well at professional events and championships. In 2021, the combined team of Rosseti Tyumen JSC won prizes in the Open Corporate Championship of Professional Excellence of Rosseti PJSC Young Professionals according to the WorldSkills methodology.

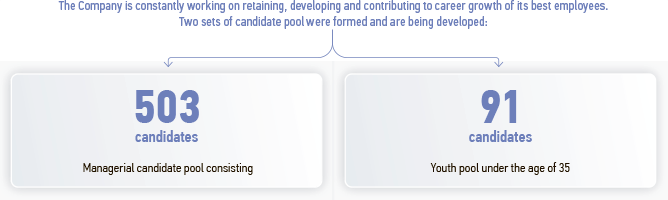

Candidate pool is formed at all levels of management and covers all positions from the operations manager to the top manager. As a result of candidate pool development measures, candidate pool covers 95% of the targeted positions.

When selecting personnel for vacant management positions, priority is given to candidates, including young specialists of the Company, and only in exceptional cases – to the best specialists in the industry recruited by competition. The Company seeks to create conditions that enhance the personnel efficiency and their involvement in solving corporate tasks. Candidates are actively involved in training events, advancement trainings and competitions held by Rosseti PJSC and Rosseti Tyumen JSC. In 2021, the Company’s candidates became the winners of the 2nd All-Russian competition “Energy Leaders”, Interregional professional competition for the personnel of the RPA and APCS of Rosseti PJSC’s SDCs.

reserve target

posts

Labor productivity improvement

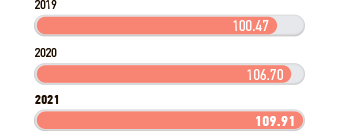

Improvement of labor productivity is a key performance indicator of the Director General of Rosseti Tyumen JSC.

In accordance with the order of the Ministry of Economic Development of Russia No. 748 dd. December 28, 2018, an updated methodology for calculating the KPI “Labor productivity improvement” was approved, calculated as the ratio of value added to the number of insured persons for all companies included in the perimeter of consolidated IFRS statements, in 2020 – in indicative, starting from 2021– in the target mode. The methodology provides for an annual improvement of labor productivity by 5%. In 2021, the Company exceeded the target value.

In order to achieve the relevant target values, the Company is systematically working to improve the organizational and functional structure, optimize work schedule and increase the workload of the staff, and automate business processes.

Personnel remuneration system

The Company’s social and labor relations with employees are governed by the Collective Agreement of Rosseti Tyumen JSC, where the employees are represented by the Tyumen Interregional Organization of the All-Russian Electrical Trade Union. The Collective Agreement helps balance the interests of the parties to this social partnership pursuant to the current law and the terms and conditions of the Tariff Agreement for Electric Power Industry of the Russian Federation.

Remuneration for the staff is set forth in the Regulations on the Single Remuneration System for Workers, Managers, Specialists, and Officers of Rosseti Tyumen JSC, which is an annex to the Company’s Collective Agreement.

The Regulation specifies uniform rates and salaries and procedures of calculating these rates and salaries for workers, managers, specialists, and officers; it also describes the procedure for setting forth reimbursements and incentives, as well as a system of bonuses and other rewards.

The incentive system for employees is based on objective-based management, is consistent with the Company’s objectives and Rosseti PJSC’s strategy, and contains a number of KPIs designed with such objectives in mind.

Key performance indicators revolve around the Company’s priorities and are balanced for each functional focus area.

Cascading is one of the key principles behind KPIs; it stipulates that the goals and objectives of each higher level are translated or decomposed onto lower levels in order to involve all of the Company’s staff in the pursuit of the same. The remuneration system also uses cross-functional assessments, in which certain indicators become part of related functional verticals.

Incentives for top managers are based on the Director General’s KPIs translated for senior managers and cascaded onto the personnel of the Head Office’s and branches’ subdivisions.

As of year-end 2021, the average pay rose by 3.0% YoY to 109.9 thousand rubles per month.

Average monthly pay of staff in 2019-2021, thousand rubles

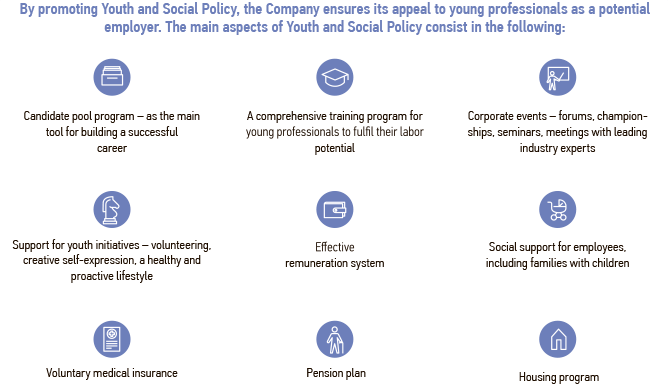

Youth policy

The Youth Policy of Rosseti Tyumen is aimed at promoting the professional growth of young employees and attracting talented young professionals to work for the Company.

The Company’s Youth Policy identifies three areas of activity:

- increasing the attractiveness of Rosseti Tyumen as a future employer, popularizing the profession of a power engineer, generating interest in the Company’s activities;

- development of mutually beneficial cooperation with specialized higher and vocational educational institutions;

- labor socialization and adaptation of young professionals in the corporate environment of the

Company, as well as promoting advanced training, professional growth of young specialists, development of professional and leadership qualities, a proactive life stance and production initiative.

Schoolchildren activities

Career guidance for school students, aimed at building a positive image of the electric power industry through the prism of digital technologies, as the most attractive industry for professional self-realization, as well as increasing awareness and loyalty to the Rosseti brand as the largest industry employer, begins with career guidance events in grades 8-9 of general education institutions.

Graduates of the 9th grade have the opportunity to become students of specialized energy groups of institutions of vocational education or transfer to the 10th grade and continue their education in specialized energy classes of general education institutions.

On the Company-served territories, 3 energy classes for high school students were created and are in operation (in the cities of Surgut, Nizhnevartovsk, Novy Urengoy). The training program in energy classes involves advanced training in engineering disciplines, meetings with representatives of the energy sector, open lectures, tours of grid facilities, as well as engaging the project’s participants in research activities.

The Rosseti Group’s Olympiad for Schoolchildren became an annual event. The main objective of the project is to discover gifted high-school students capable of engineering creativity and innovative thinking. The intellectual competition is held remotely in two stages. In the qualifying round, the jury evaluates the knowledge of teenagers in physics, mathematics and computer science. In the second stage, school students solve cases aimed at testing their creativity and ability to put knowledge into practice. Prize-winners and total winners are awarded with memorable prizes and diplomas at the HQ of Rosseti PJSC in Moscow. As a bonus, power engineers invite winners to take part in the Energy Project Session in one of the best children’s health centers in the country. In 2021, 208 schoolchildren from the region took part in this project.

As part of developing partnerships and strengthening ties with educational organizations in the region, in 2021, Rosseti Tyumen organized an online championship in mind games for students from schools, lyceums and universities. The tournament brought together more than 60 students and was held by video conferencing Representatives of educational institutions of the KhMAO and YNAO took part in the intellectual tournament. Schoolchildren and students from Surgut, Nizhnevartovsk and Novy Urengoy competed in the most popular types of intellectual games: “What? Where? When?”, “Multi-games” and “Scrabble Quartet”. The contestants who made the podium were awarded with diplomas and valuable gifts.

The most motivated graduates of energy classes and participants of corporate projects for schoolchildren enter universities that are partners of Rosseti Tyumen. After graduating, they can join the Company because social policy is primarily aimed at developing the regional economy so that young people choose in favor of working at our territory of presence in the three constituent entities of the Russian Federation.

Student activities

Компания на постоянной основе поддерживает и развивает взаимовыгодные отношения с образовательными организациями, осуществляющими подготовку профильных кадров в регионах присутствия. Заключено более 20 соглашений о сотрудничестве с образовательными организациями, созданы 2 базовые кафедры для подготовки студентов образовательных организаций высшего образования на территории присутствия компании.

The Company systematically maintains and seeks mutually beneficial cooperation with specialized educational institutions that provide specialized training the Company-served area. More than 20 cooperation agreements with educational organizations were signed, 2 specialized departments were created to train students of educational organizations for higher education in the Company-served area.

Across nine branches of Rosseti Tyumen, 507 students worked at the Company’s facilities during field training in 2021, 67 of them on a reimbursable basis.

In order to select candidates for the Company in 2021, a six-month internship was organized for 12 full-time senior university students.

Within the framework of the current scholarship support program aimed at encouraging students of educational organizations with which the Company has cooperation agreements, 15 scholarship agreements were concluded this year.

To provide for a practice-oriented preparation of students of energy fields, and for their professional commitment to work in the Company, as well as the revival of traditions of labor education of the youth, Rosseti Tyumen recruited 103 energy students in the summer working season of 2021. In terms of location, the workplaces of the members of the Energetik student brigade were in nine branches of the Company. The employment period was one and a half months.

In 2021, an agreement was signed on the implementation of the EMF Yugra Educational Energy Grid project, the parties to which are Rosseti Tyumen JSC, Nizhnevartovsk, Surgut, Yugra State Universities, as well as the Department of Education and Youth Policy of the Khanty-Mansi Autonomous Okrug – Yugra. The agreement is aimed at providing enterprises of the fuel and energy complex of the Khanty-Mansi Autonomous Okrug – Yugra with qualified personnel.

The Company also involves its employees in teaching activities, including through membership in the State Examination Commission for the defense of graduation theses.

Young professionals activities

In 2021, young specialists of the Company took part in events and projects aimed at developing project and team work skills, managerial competencies, involvement in the industry youth agenda:

- the Youth Electricity Council under the Ministry of Energy of the Russian Federation (Youth Council for Electricity); - competitions between teams of the youth league of the CASE-IN championship;

- educational project Ugra Business Management Cup Point of Growth;

- International Youth Scientific and Practical Forum Oil Capital.

As part the scientific and engineering activities of the Council of Young Professionals, Rosseti Tyumen JSC traditionally holds the Research Paper Competition among young professionals of the Company, which is focused on involving young people in solving pressing production issues, enhancing scientific and engineering creativity and discovering young potential.

Occupational health and safety, industrial safety (including fire safety)

Occupational health and safety management

Rosseti Tyumen JSC’s Occupational Health and Safety Policy prioritizes life and health of the employees over the Company’s economic performance.

Rosseti Tyumen JSCconsistently seeks to reduce the risks of occupational diseases and prevent occupational injuries.

Pursuant to the Labor Code of the Russian Federation and in order to improve the performance of its Occupational Health and Safety Management System, Rosseti Tyumen JSC has Regulations on the Occupational Health and Safety Management System that was put into force by Order of Rosseti Tyumen JSC No. 373 dd. October 1, 2021. The document sets forth the OHS Policy and the procedures of the Occupational Health and Safety Management System (“OHSMS”).

Rosseti Tyumen JSC’s OHSMS seeks to prevent occupational injuries and diseases, teach the employees the principles of safe work and hazard prevention, and continuously improve the labor conditions. OHSMS was established with a focus on continuous betterment of the effort to preserve lives and health of the Company’s and third-party employees.

Rosseti Tyumen JSC’s injury prevention and OHS improvement efforts are organized in compliance with its Comprehensive Staff Injury Risk Reduction Program 2020–2021 and Comprehensive Third-Party Injury Risk Reduction Program as approved by Rosseti Tyumen JSC’s Order No. 77 dd. February 25, 2020.

With respect to occupational health and safety, Rosseti Tyumen JSC mainly undertakes to:

- provide a healthy and safe working environment;

- consistently and continually reduce occupational injury and disease incidence;

- create and maintain a positive image as an employer;

- teach the employees to work safely and prevent hazards at work;

- create an advanced corporate culture of safety;

- continuously improve labor conditions.

* Fires resulting from technological incidents.

Fire Safety

In 2021, three fires were reported to happen at Rosseti Tyumen JSC’s facilities; investigations did not reveal any fire safety breaches. Fires resulted from:

- fires occurred at third parties – 2;

- emergency operation of the power grid – 1.

In order to improve fire safety and to prevent fires, the Company’s branches organize monthly Occupational Safety Days and conduct fire safety inspections as part of those events. The inspections produce lists of steps to address the identified breaches.

Ever since 2015, the branches also participate in the competition for best fire safety. Kogalym Electric Grids won the competition in 2021.

As part of the training of fire safety personnel, 3,628 scheduled fire drills and 187 joint drills were held with units of the EMERCOM, authorities, municipal governments and organizations located in the Company’s regions of operation.

trainings carried out

in 2021

Share of total personnel represented in the official joint committees for health and safety, with the involvement of managers and employees that monitor, and make recommendations on, occupational health and safety programs

Rosseti Tyumen JSC has structural units responsible for industrial safety and production control (“ISPC units”, “ISPCU”) that employ specialists trained in Occupational Health and Safety.

Pursuant to Article 218 of the Labor Code of the Russian Federation, Rosseti Tyumen JSC has by virtue of organizational and administrative documents established committees (commissions), which on a parity basis consist of persons representing the employer and the elective body: Primary Trade Union.

These committees (commissions) are mainly tasked to elaborate coordinated managerial decisions on how to improve the Company’s OHSMS, to ensure compliance with OHS requirements, to prevent occupational injuries and diseases.

Occupational health and safety commissioners have been elected by the staff of each production unit; these officers are guided by the Labor Code of the Russian Federation, other laws and regulations applicable to OHS.

In total, 114 OHS commissioners were elected in Rosseti Tyumen JSC. In 2021, 42 such commissioners had training. In 2021, OHS commissioners ran 777 audits and made 393 proposals, 369 of which were followed by the employers in 2021, and 24 scheduled for completion in 2022.

Occupational injury and disease

Occupational injury types and incidence, occupational disease incidence, lost-day and absenteeism coefficients, total casualties: breakdown by regions and gender

No occupational disease cases were registered at Rosseti Tyumen JSC in 2021.

In 2021, Rosseti Tyumen JSC had four industrial accidents in which four employees of the Company were injured (for the relevant period in 2020, there was one accident in which one employee of the Company was injured).

There were no accidents as a result of electrical shock in 2021 (for the relevant period in 2020, there was one accident in which one employee of the Company was injured).

The overall injury frequency rate in 2021 is 0.54.

The fatal injury frequency rate in 2021 is 0.

Occupational accidents were investigated pursuant to Article 227 of th Labor Code of the Russian Federation, in full compliance with Resolution of the Ministry of Labor and Social Development No. 73 dd. October 24, 2002 On the Approval of Forms for the Investigation and Reporting of Occupational Accidents, Regulations on the Investigation of Occupational Accidents in Specific Industries and Organizations (revisions No. 103n dd. February 20, 2014, and 640n dd. November 14, 2016).

As a result of the investigation into said accident, acts of the established form were produced, orders were issued in the branches:

- Noyabrsk Electric Grids – dd. April 21, 2021 No. 250 On priority measures to prevent injuries when using road transport;

- Noyabrsk Electric Grids – dd. May 13, 2021 No. 305 On the organization of safe maintenance of the territories of production bases in winter season;

- Nefteyugansk Electric Grids – dd. May 20, 2021 No. 376 On the results of the investigation into severe accident on April 18, 2021;

- Urai Electric Grids – dd. 11/25/2021 No. 641 On the results of the investigation into the accident with Denisov A. A., – in which the implementation of measures aimed at preventing similar accidents is prescribed.

Jobs at High Risk of Occupational Injury or Disease

Power engineering is one of the areas where the risk of injuries is rather high. That is why Rosseti Tyumen JSC lays a special emphasis on OHS.

Rosseti Tyumen JSC’s OHS Policy sets forth objectives pertaining to creating a safe and healthy working environment, prevention and maximum possible reduction of occupational risks that could compromise the health of employees, including those of contractors working at Rosseti Tyumen JSC’s grid facilities.

The Company’s OHS objectives are set by the management with the account of the following:

- requirements of regulatory acts;

- occupational risk assessments;

- opinions of workers and their representatives.

OHS objectives are analyzed and assessed with the use of indicators reflecting performance and efficiency of measures of the Occupational Health and Safety Management System (OHSMS) procedures. The main indicators are:

- reduction in accidents and injuries at work;

- reduction in the incidence of occupational diseases;

- reduction in the number of hazardous jobs;

- reduction in jobs associated with high or moderate occupational risks;

- number of employees whose medical checks identify no contraindications, precautions, or limitations;

- reduction in breaches of the OHS requirements on the part of employees, contractors (subcontractors) or other parties at Rosseti Tyumen JSC’s power grid facilities;

- reduction in OHS breaches identified during OHSMS inspections by governmental supervision agencies;

- number of actions taken upon the remarks and comments issued by the governmental supervision agencies after inspecting the OHSMS;

- reduction in accidents and injuries of third-party (subcontractor) employees and other persons present at Rosseti Tyumen JSC’s grid facilities;

- number of OHS-related meetings and consultations with employees and their representatives, including the meeting of the OHS Committee;

- number of implemented and executed resolutions of Rosseti Tyumen JSC’s executives that were made upon previous OHSMS inspections;

- the amount of funds for benefits and compensation to employees employed in work with harmful and/dangerous working conditions;

- funding of benefits and compensations for employees working in hazardous and/or harmful environments;

- funding of OHS activities.

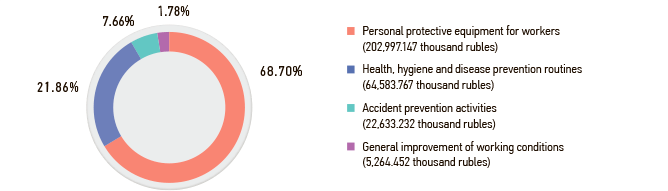

In total, 295,478.598 thousand rubles was spent on OHS activities in 2021, including:

OHS Matters in Official Agreements with Labor Unions

Occupational health and safety matters are described in the Occupational Health and Safety section of the Collective Agreement 2019-2021 (edition No. 1 dd. December 17, 2021, and No. 2 dd. December 29, 2021). This Section stipulates:

- Mandatory social insurance against occupational accidents and diseases.

- Ensuring that the safety and labor conditions of each workplace and each facility/site are compliant with the state occupational safety regulations.

- Evaluating the labor conditions at workplaces to elaborate and take measures for occupational safety and labor condition improvement.

- Training the workers hired for harmful and/or hazardous jobs to use safe methods and techniques in their work, which is supplemented with workplace training and exams; training employees to provide first aid in case of an occupational accident, using state-of-the-art training technology and advice from qualified instructors.

- Timely development of occupational safety rules and regulations with due account of the opinion submitted by the elected body of the Primary Trade Union in due order.

- That employees working in harmful and/or hazardous environments, at extreme temperature, or at contaminated facilities, be provided duly certified protective clothing, shoes, and other personal protective equipment, as well as special food and detergents/disinfectants pursuant to the applicable standards.

- Employer-funded pre-employment and periodic medical checkups; mandatory psychiatric examinations for some jobs; in the implementation of certain types of professional activities of mandatory psychiatric examinations.

- Measures to Improve Occupational Safety and Labor Conditions, Preserve Life and Health of Employees.

Besides, Rosseti Tyumen JSC trains its OHS commissioners, provides them with access to standards, occupational safety rules and instructions. These commissioners have four hours a week to perform their duties, paid at the same rate as their primary jobs.

Safety Training for Employees

In order to set forth uniform requirements to staff management, the Company’s has developed and adopted its Staff Management Standard applicable to people working at the Company’s active energy facilities, which was approved and put into force by Order of Rosseti Tyumen JSC No. 261 dd. July 13, 2021; the Standard, among other things, regulates testing employees’ knowledge of safety regulations, regulatory standards, user manuals of electrical installations, OHS guidelines, fire safety regulations, and other rules and instructions provided by public supervisory agencies.

All employees are trained and tested in occupational health and safety pursuant to Tyumenenergo JSC’s Occupational Health and Safety Testing Routine approved and put into force by Order of Tyumenenergo JSC No. 294 dd. May 21, 2019; specialized training institutions are involved in the process. The Company organizes workmanship contests, OHS briefings and workshops, first-aid trainings, etc. All these activities are consistent with the programs, regulations, and other effective documents.

Rosseti Tyumen JSC has OHS briefings that comply with the legislative requirements. Briefings are tailored to each employee category and falls into the following classes:

- introductory;

- primary on-site;

- repeated;

- unscheduled;

- special.

All briefings are conducted by specially trained and duly qualified employees during working hours at a frequency set forth in the regulatory documents and guidelines.

For the training purposes, Rosseti Tyumen JSC uses ASOP Expert, an automated personnel training system recommended by Rosseti PJSC and Rostekhnadzor. The training sessions take place in special computer-equipped classrooms and at some workplaces that have remote access to ASOP Expert (network edition).

The following classes take place in OHS classrooms: pre-examination training, exams, first aid training. The following programs are used: ASOP Expert for pre-examination and GOSHA, a robotized doll, for first aid training.

This software and hardware allow for detailed studying of the operating instructions, fire safety instructions, and OHS guidelines, as well as acquire first aid skills. Key functions and activities of the OHS classrooms are:

- training staff to work safely and to use necessary protective means;

- studies of OHS regulations and standards;

- familiarizing with hazardous and harmful production factors by which the workers can be affected at workplaces;

- OHS briefings, thematic lessons and OHS knowledge testing;

- simulator-enabled first-aid training with a focus on accidents;

- learning the equipment designed to protect from exposure to occupational hazards and harm.

OHS classrooms are equipped with stands, OHS banners, and TV sets to watch educational films and carry out training sessions.

OHS information desks have the relevant information on the conducted workplace inspections, reviews of the injury rate in the electric power industry, and OHS memos.

Measures to ensure health and safety of employees during work

Rosseti Tyumen JSC has 50 OHS classrooms to comply with the OHS requirements applicable to staff management, prevent occupational injuries and diseases, and verify workers’ preparedness and fitness for their jobs. Rosseti Tyumen JSC’s OHS classrooms are equipped in compliance with the Recommendations for Organizing OHS Classrooms and Information Desks as approved by Resolution of the Ministry of Labor and Social Development No. 7 dd. January 17, 2001; and with the OHS Classroom Standard for Electric Power Companies as approved by Order of the RAO UES of Russia dd. September 27, 2001, RD 153–34.03.107–2001.

The Company established a system to respond to OHS breaches pursuant to the Regulations on Responding to OHS Breaches Committed By Employees of Rosseti PJSC’s Subsidiaries and Affiliates as approved by Decree of Rosseti PJSC No. 114r dd. March 6, 2017 and put into effect in Rosseti Tyumen JSC by Decree No. 191 dd. March 30, 2017 On Staff Injury Prevention System.

The System is based on Three Befores and is in line with the Regulations approved by Decree of Rosseti PJSC No. 114r dd. March 6, 2017 and put into effect in Rosseti Tyumen JSC by Decree No. 191 dd. March 30, 2017 On Staff Injury Prevention System.

The Zero Injuries Action Plan “Vision Zero” in Rosseti Tyumen JSC is approved and implemented in Rosseti Tyumen JSC. The concept of “zero injuries” Vision Zero is a series of actions aimed at improving the culture of work, safety, the OHS priority, changing the attitude towards OHS in the minds of employees. The subject matter of the Concept is the introduction of a risk-based approach to the OHS system by analogy with foreign experience in accordance with the international standard ISO 45001 “Occupational health and safety management systems. Requirements with guidance for use”.

The Company works to make sure that officers listed in job orders fully adhered to Guidelines on Primary Authorization to Work Under Job Orders / Guidelines on Repeated Authorization to Work Under Job Orders (approved by Decree of Rosseti PJSC No. 353r dd. July 11, 2017; put into force by Order of Rosseti Tyumen No. 395 dd. July 18, 2017 On Better Specialized Briefings).

In order to ensure safe and normal work environments at all production stages, compliance with OHS requirements at all management levels, enhancement of the efficiency and responsibility of officers organizing and supervising the efficiency of the OHSMS and Internal Technical Control System (ITCS) during the “Days ‘Since’”, the Company conducted inspections of compliance with current OHSMS and ITCS requirements, including compliance with them by officers of the Company’s subdivisions who are responsible for implementation of such requirements. Following the identified violations, directors of the Company’s subsidiaries were given the instructions; execution of such instructions was supervised by the specialists of the Industrial Safety and Production Control Services.

Upon detecting any breach of safety or any industrial hazard, Rosseti Tyumen JSC’s employees can use any available method to report their finding to the manager and to the Industrial Safety and Control Unit by phone, memo, or other channels. Rosseti Tyumen JSC adopted the Rosseti Group of Companies OHS Policy, and also developed and approved OHS guidelines by positions and type work.

Injuries and Casualties of Non-Employees at the Company’s Facilities

There were no injuries and casualties of non-employees at the Company’s facilities in 2021.

Environmental protection

Environmental policy

By Resolution of its Board of Directors No. 25/20 dd. September 17, 2020, Rosseti Tyumen JSC joined the Power Grid Complex Environmental Policy and approved it as an internal document of Rosseti Tyumen JSC.

The Policy mainly seeks to preserve a favorable natural environment for the current and future generations.

Decree No. 260r dd. December 7, 2021 approved the Action Plan for the implementation of the Policy for 2021-2022.

The main areas of commitments undertaken to protect the environment, aimed at the implementation of the Policy, include:

- compliance with the requirements of the environmental legislation of the Russian Federation;

- reduction of negative impact on the environment;

- application of voluntary environmental responsibility mechanisms.

Environmental Management System (EMS)

The Environmental Management System is a part of the integrated management system used to develop and achieve the objectives of the environmental policy, manage the environmental aspects of the Company’s activities.

The EMS has been in place in the Company since 2008. It is a tool which improves the performance and effectiveness of the environmental safety activities. To that end, Rosseti Tyumen JSC has:

- identified the processes focused on environmental safety;

- identified the sequence and interconnection of these processes;

- defined the criteria and methods of evaluating the performance of the EMS;

- provided the availability of resources for the EMS functioning;

- undertaken to continuously monito and measure environmental safety;

- undertaken to continuously improve the EMS processes.

In the structural divisions of the Company in 2021, actions were carried out to update and assess the significance of environmental aspects that can be managed and influenced. A register of significant environmental aspects and impacts of Rosseti Tyumen JSC on the environment was compiled.

The Company determined key environmental performance indicators for 2021-2022 related to environmental aspects, and planned appropriate activities to achieve the intended results.

In 2021, the cross internal audit of the EMS was carried out in all branches of the Company. Internal audits of the EMS and inspections within the framework of the ITCS were carried out by independent auditors in such a way that during their implementation complementary tasks were solved, aimed at identifying non-compliance with the requirements of ISO 14001:2015 and the environmental legislation of the Russian Federation.

In the period from 27.09.2021 to 08.10.2021, the Company conducted the first supervisory audit of the integrated management system, including an audit of the EMS for compliance with the requirements of ISO 14001:2015. As part of the external audit, the structural subdivisions of the executive office, the Surgut, Noyabrsk, and Northern Electric Grids branches were examined.

The audit report confirmed that the Company implemented and maintained an EMS, the areas for improvement are identified; the certificate of compliance with ISO 14001:2015 was extended.

In accordance with the principles of the functioning of the EMS, the Company intends to further improve the condition of its environmental protection activities.

Environmental performance

Air Protection

Air pollutants come from the exhausts of the Company’s facilities such as welding stations, metal machining sites, vehicle M&R facilities, garages, carpentry shots, repair shots, paint shops, and diesel generators (used as backup power sources).

Besides, Noyabrsk and Northern Electric Grids operate natural gas-fired low-power heating plants. Kogalym EG operates a crude oil-fired heating plant.

The Company tests the performance of its dust and gas collectors on an annual basis.

In 2021, the Company’s facilities release of air pollutants remained at the level of 2020. (28.476 tons) and amounted to 28.23 tons. For the period 2019–2021, the volume of emissions was the lowest in 2019 (27.626 tons), and the highest – in 2020 (28.476 tons).

Emissions of pollutants in 2019-2021-2020, tons

Gross emissions of pollutants into the air across Rosseti Tyumen JSC in 2019-2021, tons

solid

gaseous, including

sulfur dioxide

carbon monoxide

nitrogen oxides (in terms of NO 2 )

volatile organic compounds

Other

Protection and Rational Use of Water Resources

Rosseti Tyumen JSC’s branches operate artesian wells, mainly for process needs. Nizhnevartovsk EG also uses groundwater as tap and household water.

Rosseti Tyumen JSC is a party to 16 licensing agreements as a subsoil user.

In 2021, the Company complied with the terms and conditions of such agreements in full. Water from artesian wells was tested for quality. Tests proved the quality was no worse than required by the licensing agreements (subsoil licenses). No artesian well was plugged or shut.

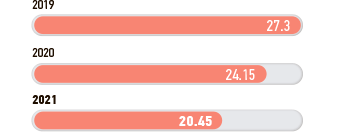

20.45 thousand m3 of groundwater was extracted in 2021, which is a 15% decrease against 2020 (24.15 thousand m3) and a 25% decrease against in 2019 (27.3 thousand m3). This reduction was due to the change in the technology of operating the pumped artesian well of Nizhnevartovsk Electric Grid and a partial transition of personnel to remote work in all branches of the Company.

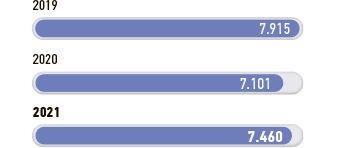

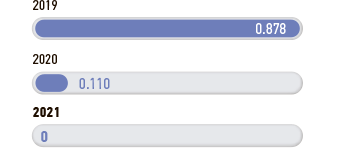

Water extracted in 2019-2021, tons

Waste management

Rosseti Tyumen JSC is licensed to collect, transport, process, dispose of, neutralize, or emplace waste of Hazard Classes I to IV (License No. 66-8956 TOB dd. February 27, 2020).

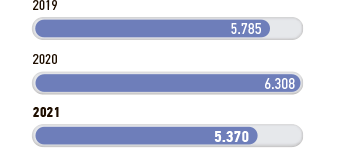

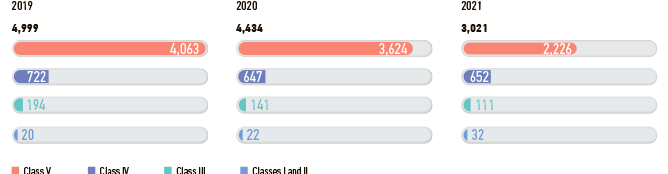

In total, 3,021 tons of waste were generated in 2021, which is a 32% decrease against 2020 (4,434 tons).

Уменьшение общего количества образования отходов в 2021 году относительно 2020 года произошло за счет сокращения отходов:

Waste generation in the Company over the past three years shows a systematic decrease:

- in 2019 – 4,999 tons;

- in 2020 – 4,434 tons;

- in 2021 – 3,021 tons.

The decrease in the total amount of waste generation in 2021 as compared to 2020 was due to the reduction of waste:

- Class 1 – extreme hazard;

- Class 2 – severe hazard;

- Class 3 – moderate hazard;

- Class 4 – low hazard;

- Class 5 – almost no hazard.

In 2021, 1,514 tons of waste sent for processing, neutralization, and disposal. This indicator decreased compared to previous periods: 3,159 tons in 2020 (-52%) and 2,926 tons in 2019 (-48%). This is due to a decrease in the total amount of generation and transfer for recycling of ferrous scrap, aluminum scrap in 2021.

In 2021, waste sent to specialized landfills remained practically unchanged compared to 2020 (-4%), but decreased compared to 2019 (-23%).

Environmental protection costs

Funding of the Environmental Program mainly goes into ensuring the Company’s compliance with Russia’s environmental laws, international standards, and local corporate standards.

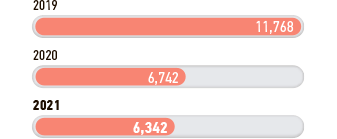

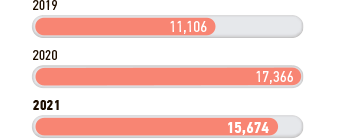

Of the costs of environmental protection in 2021:

- air protection, including instrumentation designed to measure the impact of the Company’s production facilities on the air, an effort that involved specialized accredited centers and included the verification of gas analyzers – 1,065 thousand rubles;

- protecting water bodies, including wastewater treatment (drainage into centralized sewerage systems and pumping out of septic tanks), water quality tests, etc. – 6,342 thousand rubles;

- land protection, including the disposal, neutralization, and emplacement of waste, disposal of stormwater from SS oil collectors, etc. – 20,129 thousand rubles;

- biodiversity conservation, including the purchase and installation of bird protections – 15,674 thousand rubles.

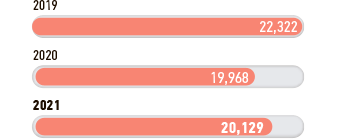

Environmental costs incurred by Rosseti Tyumen JSC in 2019-2021, thousand rubles

water protection costs

air protection costs

soil protection costs

BD purchase and installation costs

Total

There was a reduction in the cost of purchase and installation of bird protection (from 17,366 thousand rubles in 2020 to 15,674 thousand rubles in 2021). This decrease is due to a decrease in the number of installed BPDs (in 2021, 3,740 units were installed, in 2020 – 5,765 units).

The costs for air protection increased from 434 thousand rubles in 2020 to 1065 thousand rubles in 2021. The increase in costs is due to the development in 2021 of documentation for air protection (draft standards for permissible emissions, an inventory of stationary sources and emissions of harmful (pollutant) substances into the air, measures to reduce pollutant emissions during periods of adverse weather conditions).

Pursuant to the legislation of the Russian Federation, the environmental impact fee, calculated based on the results of 2021, will be calculated and added no later than March 1, 2022.

How the company protects air, water, soil and land

Rosseti Tyumen JSC’s activities have little impact on the environment.

The Company’s branches use sphagnum-based petroleum sorbents to localize pollution in case of transformer oil spillage.

These sorbents use a unique technology and have several advantages, as they are naturally capable of biodegrading the absorbed hydrocarbons whilst having a high absorption capacity. The sorbents are perfectly natural, organic, easy to transport and use. This practice showcases the Company’s usage of advanced, safe, and unique technology to make its grid facilities environmentally safe.

Conservation of biodiversity in the Company-served regions is another priority, including measures to prevent the decline in the number of birds.

To that end, the Company keeps equipping its power transmission lines with bird protections (BPs). Thus, in accordance with the multi-year plan for the installation of BPDs, 3,740 units were installed in 2021, 5,765 units in 2020, and 5,680 units in 2019.

devices installed

in 2021

Environmental Education for Staff. Environmental Campaigns and Competitions

Every year, Rosseti Tyumen JSC takes effort to educate its staff on the matters of environment, environmental law, environmental risks and their prevention.

In 2021, 83 persons were trained, of whom:

- 66 persons had training in Ensuring environmental safety – for managers and specialists of general business management systems;

- 14 persons – in Ensuring environmental safety during hazardous waste management;

- 2 persons – in Ecology and environmental safety;

- 1 person – in Environmental management and ISO-based audit.

For comparison: in 2020, 52 persons were trained (23 had training in environmental safety for managers and specialists; 29 had training in waste management).

Training costs totaled 386.3 thousand rubles (in 2020 – 429 thousand rubles). The reduction in costs with an increase in the number of trained employees was mainly due to the choice of the distance learning format in 2021.

The Company annually supports the Clean City environmental campaign. In 2021, employees of Rosseti Tyumen JSC took part in subbotnik.

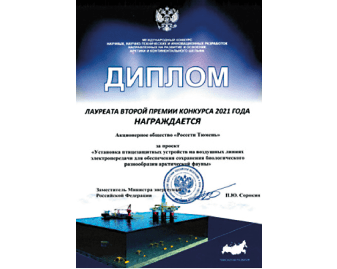

In 2021, Rosseti Tyumen JSC took part in the International Contest of Scientific, R&D, and Innovative Developments Dedicated to the Exploration and Development of the Arctic and Continental Shelf. The Installation of bird protections on OLs to ensure the conservation of the biodiversity of the Arctic fauna project was awarded the 2nd degree diploma.

The Company also participated in the annual All-Russian 2021 Reliable Partner – Ecology competition for selection of the best regional environmental practices. The Installation of bird protection devices on OLs of Rosseti Tyumen JSC to ensure the conservation of bird fauna in the Company-served territories project was submitted in the category Best Project in Biodiversity Conservation. The implementation of environmental measures of the Company aimed at conserving biodiversity positively impacts the environment and contributes to the conservation of bird population.

Industrial Environmental Control

Industrial environmental control is the main method of monitoring compliance with the environmental legislation at production facilities.

Rosseti Tyumen JSC’s industrial environmental control efforts involve specialized licensed centers for analytics and focus on two areas:

- evaluating natural environment (groundwater and surface water, air quality outside the production facilities, analysis of electromagnetic and noise parameters);

- control of technogenic facilities, including the sites of waste accumulation, platforms of in-house artesian wells, control of emission sources (flue gases of small heating plants, maintenance shops and paint stops).

A well-organized system of industrial environmental control allows evaluating the state of natural environment at the place of production facility location and timely reveal negative changes that can occur under the action of anthropogenic factors.

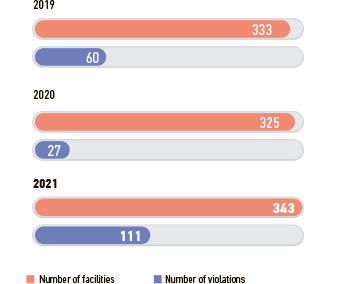

The largest number of objects (343) was audited under industrial environmental control in 2019-2021. In 2021, the number of audited objects increased by 3% as compared to 2019 (333 objects) and by 5% as compared to 2020 (325 objects).

The number of detected violations (111) in 2021 increased by 76% compared to the previous year (27) and by 46% compared to 2019 (60). Thus, in 2021, the maximum number of violations for the period 2019-2021 was detected, and in 2020 – the minimum number. A significant increase in the number of detected violations in 2021 may be due to on-site inspections. In 2020, inspections due to the sanitary and epidemiological situation were performed remotely. The remote auditing format does not allow to assess the territory of facilities for compliance with environmental safety requirements in full.

Reporting period results were as follows:

- emissions of air pollutants within the legally allowed limits;

- the quality of extracted groundwater (freshwater) in line with the license agreements;

- physical impact (noise, electric and magnetic field) does not exceed the maximum permissible level prescribed by sanitary regulations.

The number of audited facilities and identified violations as part of industrial environmental control for 2019-2021

Environmental indicators

Energy consumption and energy conservation

In 2021, energy conservation and efficiency improvement measures of Rosseti Tyumen JSC were implemented in accordance with Federal Law No. 261-FZ dd. November 23, 2009 On Energy Conservation and Improving Energy Efficiency and on Amendments to Certain Laws of the Russian Federation, Decree of the Government of the Russian Federation No. 340 dd. May 15, 2010 On Setting the Requirements for Programs in Energy Efficiency and Energy Conservation for Companies Engaged in Engaged Regulated Activities, the decision of the Regional Energy Commission of the Tyumen Region, KhMAO, YNAO No. 31 dd. December 12, 2019, and also pursuant to Rosseti Tyumen JSC’s Energy Conservation and Efficiency Program for 2018-2022 (“the Program”), approved by the decision of the Board of Directors of Rosseti Tyumen JSC on May 24, 2021 (Minutes No. 13/21).

The Program seeks to:

- reduce electricity losses in transmission and generation;

- reduce electricity consumed by substations;

- reduce the use of fuel and energy in production;

- optimize and improve Rosseti Tyumen JSC’s internal business processes related to energy management.

Over the course of 2018-2021 since the Program was implemented, it saved 40,966 TOE of energy or 953.344 million rubles.

Throughout the reporting year, the Company pursued energy efficiency improvements based on the mandatory energy audit conducted in 2017.

Effects of energy conservation efforts in 2021:

Equipment with smart metering devices amounted to 70.58% of the total volume, equipment with LED lamps – 85.08% of the total volume.

The cost of implementing the Energy Saving and Energy Efficiency Improvement Program in 2021 – 248.893 million rubles, VAT exclusive.

Energy Management System

Pursuant the Integrated Management System Policy, Rosseti Tyumen JSC voluntarily follows the requirements and takes measures to reduce the in-house demand for fuel and energy.

From September 27 through October 8, 2021 the Company underwent an independent audit that produced a certificate certifying that the Company’s Head Office and branches operated an energy management system compliant with ISO 50001:2018.

*The deviation between the indicators of 2021 and 2020 is due to weather conditions: the average ambient temperature in 2021 was lower than in 2020; HDD indicator increased by 14/3% in the Tyumen region, by 24.6% in the Khanty-Mansi Autonomous Okrug – Yugra, by 25% – in the YNAO. In addition, the number of the Company’s employees performing their duties remotely decreased from 24% to 17%.

Development of the regions of operation (GRI 102-16, 201-1, 102-42)

Contribution to the Development of the Regions of Operation

Rosseti Tyumen JSC is guided by the principles of sustainable development and strives for economic efficiency, a balance of public interests and natural and environmental potential. The Company understands that investments in infrastructure are an important aspect of corporate social responsibility, since the Company’s enterprises are located in three regions of the Russian Federation: Tyumen region, KhMAO-Yugra and YNAO.

Rosseti Tyumen shares and supports the sustainable development goals for the period up to 2030, realizing that the electric power industry plays an important role and makes a significant contribution to the well-being of society. The Company takes into account the possible socio-economic consequences of the decisions made and maintains a dialogue with all stakeholders through the provision of public reporting and the implementation of social programs.

Impact on the local community

Rosseti Tyumen JSC is convinced that the development of the Company-served territories is an important part of the implementation of the Company’s strategic goals. Given the geography of operations, we focus on maintaining stable jobs, strengthening a positive image and public trust as one of our main goals.

Reliable and high-quality electricity delivery to consumers in the Tyumen region, KhMAO-Yugra and YNAO is the priority for Rosseti Tyumen JSC, a backbone enterprise of the macroregion. Contributing to the improvement of investment appeal and the growth of the economic potential of the territories, the Company implements projects for the construction and modernization of the power grid infrastructure.

Rosseti Tyumen JSC actively cooperates with the governments of the Tyumen Region, KhMAO-Yugra and YNAO on synchronization of plans for the development of territories and the Company’s grid facilities. Thus, power engineers are members of the coordinating bodies for preparing Power Industry Development Roadmaps (PIDR) of three constituent entities of the Russian Federation and participate in preparing PIDR.

In 2021, Rosseti Tyumen JSC signed an agreement with the Government of the Tyumen Region aimed at ensuring reliable and high-quality electricity delivery to consumers, planning the development of municipalities in terms of locating grid facilities and creating outdoor lighting networks, as well as developing the investment potential of the region.

In the Q3-Q4 of 2021, Rosseti Tyumen JSC put into operation facilities for power supply of oil and gas fields located in KhMAO-Yugra and YNAO. Some of them were built by the Company at a record-breaking pace. The total investment of power engineers in the economy of the regions amounted to about 8.5 billion rubles.

In 2021, the energy company allocated more than 4 billion rubles for the implementation of the maintenance and repair program for the power grid.

Rosseti Tyumen JSC systematically works to comply with the requirements of the environmental legislation of the Russian Federation, increase the level of industrial and environmental safety, and reduce the negative impact of production activities on the environment.

power engineers in the economy

regions

Taxes paid in 2021: breakdown by budget (rubles)

Minimum pay in the regions of operation ( GRI 202-1 )

The minimum wage (taking into account regional coefficients and northern allowances) in all branches of the Company exceeds the living wage for the able-bodied population established in the regions of operation.

Ratios of average pay in Rosseti Tyumen JSC to the average pay in the Company’s region of operations (rubles)

Adhering to the principles of social responsibility, the Company primarily hires employees (including managers) from among the representatives of the local population. More than half of the top managers of the Company in the regions of operation are hired from among the local population. In the reporting period, the Company did not produce any impact related to the need to relocate residents ( GRI 202-2 ).

Investments in public infrastructure and charity ( GRI 203-1 )

In addition to the timely payment of taxes, Rosseti Tyumen JSC makes a significant contribution to the social and economic development of the regions it serves, implements social programs and projects that contribute to their sustainable development.

In 2021, power supply of socially significant facilities was organized:

- 24 rural medical posts in Southern Tyumen region;

- a branch of the Nizhnetavdinsky secondary school in the village of Kuskurgul, Nizhnetavdinsky district;

- kindergartens in Degtyarevo of the Tobolsk region and Evsino of the Golyshmanovsky district;

- drinking water treatment unit in the Tobolsk region – 9 pcs.;

- water supply wells – 13 pcs.;

- outdoor lighting facilities – 60 pcs.;

- boiler stations – 3 pcs.;

- country club – 4 pcs.;

- mosque – 2 pcs.

Environmental protection measures in the field of biodiversity are implemented, including bird protection (BPD). 14,963 BPDs installed from 2014 to 2021, including 3,740 BPDs in 2021. The cost of the installation of one BPD in 2021amounted to 4191 rubles a piece.

Careful and attentive attitude to the environment is an integral part of the policy of a responsible Company. In accordance with the precautionary principle, Rosseti Tyumen JSC aims to avoid any anticipated environmental damage, even in the absence of any scientifically proven data that a certain activity causes such damage. Decisions on the elimination or minimization of the negative impact on the environment are made at the design stage of power grid facilities.

Efforts to prevent the spread of COVID-19 in the regions of operation

During the coronavirus pandemic in 2021, Rosseti Tyumen JSC, as the key infrastructure organization in Western Siberia, provided comprehensive support to companies, institutions and residents in the areas of operation, being in constant interaction with the regional authorities.

The need for a prompt response related to the COVID-19 pandemic prompted the Company to introduce drastic restrictive measures, the main task of which was to preserve the Company’s main value – its employees, ensuring the reliability and uninterrupted electricity delivery to the country.

Results

In order to preserve the life and health of employees during the COVID-19 pandemic, the Company implemented the following measures:

-

COVID-19 testing

For early detection of coronavirus infection (COVID-19), as well as in pursuance of the decisions of regional authorities, the personnel of the Rosseti Tyumen JSC regularly undergoes laboratory testing by polymerase chain reaction (“PCR”), express analysis method, as well as testing at workplaces using rapid COVID-19 antigen tests. Regardless of certificates of vaccination or the past disease, the Company’s employees are tested for COVID-19 upon returning to on-site workplaces after vacation, returning from a business trip, after rest and recreation for rotational workers, after being in contact with an employee of the Company who was diagnosed with COVID-19.

Employees of the Company are tested for COVID-19 in medical institutions within the agreements signed or independently presenting the relevant to receive reimbursement.

-

Remote work

In 2021, 80% of employees of the Company’s management worked in remote mode on average. -

Anti-COVID-19 vaccination / revaccination, additional measures to support and motivate staff during a pandemic

The most effective protection measure against the novel coronavirus is vaccination. Through regular outreach to staff on the benefits of vaccination as the only way to avoid infection or complications of COVID-19, as well as providing the ability to get vaccination at the workplace, 85% of employees were vaccinated, 5% were revaccinated in 2021. In order to maintain collective immunity in the Company’s work teams (in 2021, it amounted to 80% on average), additional measures were introduced to support employees undergoing vaccination / revaccination:

- providing a day off for vaccination / revaccination;

- granting 1 additional day leave for vaccination/revaccination.

-

Providing personnel with personal protective equipment

Spending on normal working conditions and safety measures in 2021

Material costs to ensure normal working conditions and safety measures (PPE, disinfectants)Activities costs, thousand rublesFace masks, respirators1 401Medical gloves250Antiseptic, disinfectants392Total2 044 -

Maintaining the mental state of employees

In order to monitor the health of the Company’s personnel, a response center for the prevention of the spread of COVID-19 collects information on the number of sick employees and their condition via the Internet. The Company’s personnel are regularly educated on measures of preventing COVID-19, including within the trade union organization.

Human Rights Compliance

Complying with human rights is one of the core principles of Rosseti Tyumen. The Company does not accept violation of human rights in any form and manifestation at the workplaces, in interaction with business partners and other stakeholders.

The company strictly adheres to business ethics rules, showcases a responsible attitude to their employees and ensures that their work is voluntary and properly rewarded.

The Company admits its responsibility to ensure that any of its actions do not directly or indirectly contribute to the violation of human rights.

Stakeholder engagement (GRI 102-40, 102-42, 102-43)

Approach to stakeholder engagement

Stakeholder engagement is a necessary element of responsible business practices. Rosseti Tyumen seeks to balance the interests of all stakeholders in order to reduce risks and increase opportunities.

The Company develops communications based on the principle of an active, regular, constructive, and ongoing dialogue. By providing essential information on all aspects of its activities, including through non-financial reporting, Rosseti Tyumen builds trust and sincere relationships with stakeholders.

Interaction with stakeholders is performed via information channels, such as official Internet portals and the Company’s social media accounts.

The Company actively interacts with all representatives of stakeholders, by holding meetings of working bodies, seminars and thematic conferences, one-on-one meetings, press conferences, official correspondence, telephone conversations, organization of joint actions, as well as holding surveys and perception studies.

Since 2005, Rosseti Tyumen has been publishing annual reports every year. Since 2012, it has been publishing integrated reports, guided by international reporting standards for non-financial information: GRI guidelines, AA1000 Stakeholder Engagement Standard (SES). Since 2018 (from the drafting of the 2017 report), the Company has switched to reporting in line with GRI Standards. For the first time (at a deep level), the UN Sustainable Development Goals (SDGs), as well as targets and metrics within the SDGs, are integrated into non-financial reporting for 2021.

Stakeholder definition

Rosseti Tyumen aims to maintain constant communication with stakeholders. The concept of “stakeholders” covers organizations, communities and individuals that form a system of expectations and, accordingly, influence the adoption of management decisions in the Company and are, in turn, influenced by these decisions.

Rosseti Tyumen is aware of the high level of its responsibility to all stakeholders. Therefore, the business management concept of Rosseti Tyumen is focused on meeting the expectations of all stakeholders in the integrated sustainable economic, social and environmental development of the Company that meets the needs of the present and does not compromise the capabilities and aspirations of future generations ( 102-43 ).

Key stakeholders of Rosseti Tyumen

All stakeholders are divided into internal and external. As part of the preparation of the Annual Report for 2021, a ranking map of Rosseti Tyumen’s stakeholders was compiled based on a special survey of 64 external and internal stakeholders. When compiling the ranking map of stakeholders, both the economic, social and environmental impact of Rosseti Tyumen JSC’s activities on various categories of stakeholders, as well as the reverse impact of stakeholders on the Company’s activities ( GRI 102-42 ) were taken into account. The results of the survey showed that the highest level of mutual influence is observed in three groups of stakeholders:

- management bodies of the Company;

- government;

- employees and their representatives.

Stakeholder map of Rosseti Tyumen ( GRI 102-40 )

2. Transparency of the Company’s operation and management.

3. Dividend payout

2. Annual Report.

3. Federal and regional media.

4. Corporate website

2. Net loss under RAS amounted to 234 million rubles against 3.4 billion rubles a year earlier.

3. According to the results of the year, the Company’s net assets increased by 3.2% and amounted to 126.7 billion rubles.

4. The Company voluntarily discloses information in accordance with the legislation of the Russian Federation on the securities market

2. High quality service.

3. Information transparency and availability.

5. Demand for electricity and capacity covered.

4. Demand for the Company’s additional services covered

2. The Rosseti Group’s Grid Service Portal.

3. Call Center.

4. Customer surveying.

5. Corporate website of the Company.

6. Federal and regional media

2. In 2021, the Company connected 5,285 new consumers. This is 74% more than in 2020. The total capacity of the generated electricity amounted to 213 MW.

3. Through the Портал-ТП.рф portal and its mobile application, 10,744 applications for grid connection were received, which is 4.5 times more than in 2020.

4. 159,943 inquiries were received from the Company’s customers, 123,700 of them through the Unified Contact Center, which accounts for 77% of the total number of inquiries.